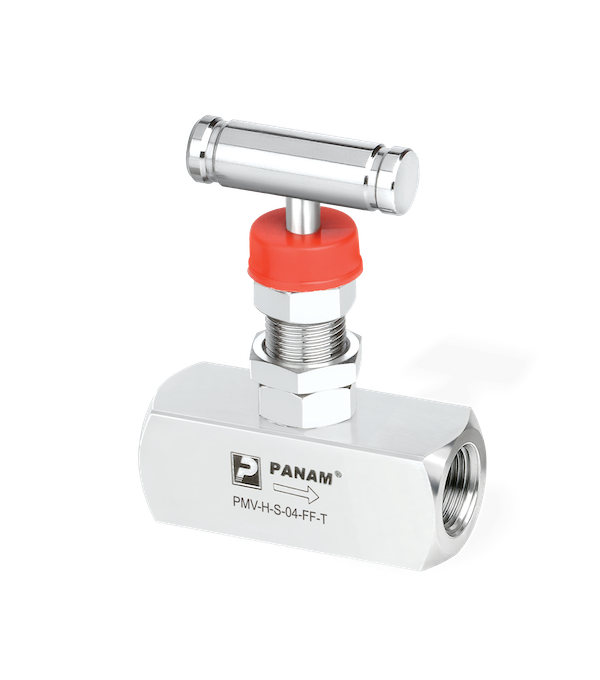

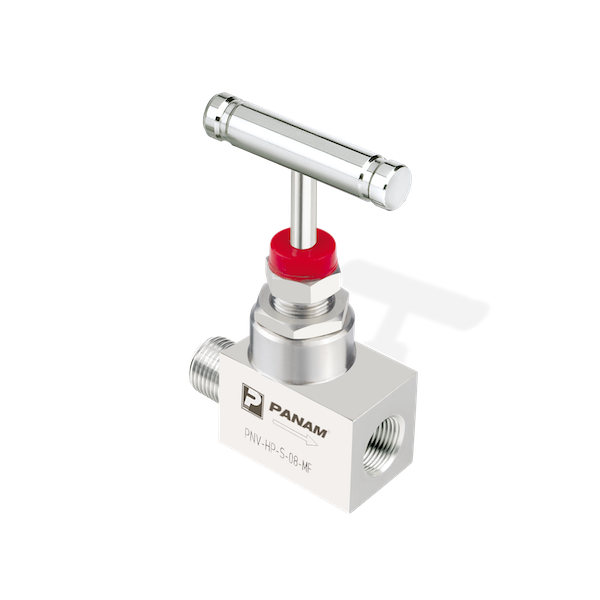

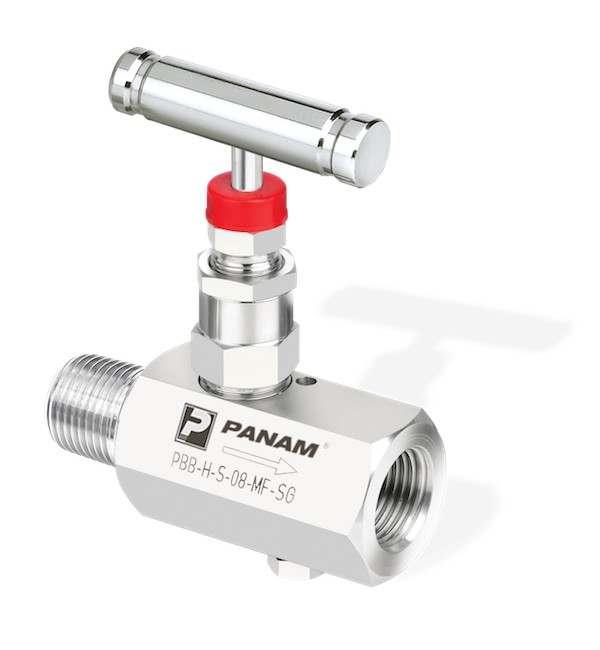

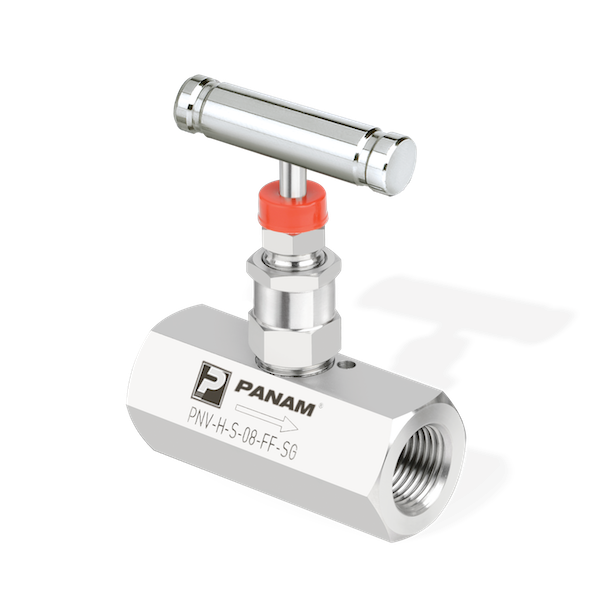

Hex Bar Needle Valves

PANAM HB Needle Valves are hex bar stock valves and are constructed out of 316 Stainless Steel (SS) or A105 Carbon Steel (CS), however exotic metallurgy is available for special order. Standard end connections include female or male threaded (NPT) however BSP, ISO, DIN, and JIS tapered pipe ends are also available.

General product features:

- Union bonnet or screwed bonnet connection

- Metal to metal seat

- Rolled and hard plated stem threads and tip stellated to prevent galling and extend life of valve

- Two-part stem tip arrangements

- Non-rotating ball tip to ensure bubble tight seal and shut-off

- One-piece body assembly

- Maximum Working Pressure (MWP)

- 6000 psi (400 bar) at 200°C

- 10000 psi (700 bar) at 120°C

- Temperature rating: -54°C to 240°C

- Built to MSS-SP-99

- ISO 9000 Certified

- High temperature model with Grafoil packing available upon request

Quality test procedure:

- Nitrogen Gas at 1200 psi (80 bar) to ensure no leakage at seal and seat

- Hydrostatic test with pure water at 1.5 times maximum working pressure (MWP)

- Optional tests including Helium and Temperature available upon request