Solar Chemical Injection Pump

Chemical Optimization Quantified

Recently, a customer of ours was looking to optimize chemical injection in a fashion that enabled:

- Remote Control Capability

- Targeted and Verified Injection Rates

- Driving down Chemical Costs by not 'over-injecting'

- Chemically Compatible in Harsh Conditions

Achieving the Goal

At $5/L, injecting 24L (6.3 Gal) daily instead of the needed 11L (2.9 Gal) quickly adds up—That's ~$65 wasted every day, or $23,725 per year on just one site.

How?

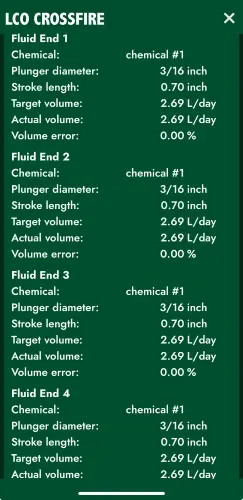

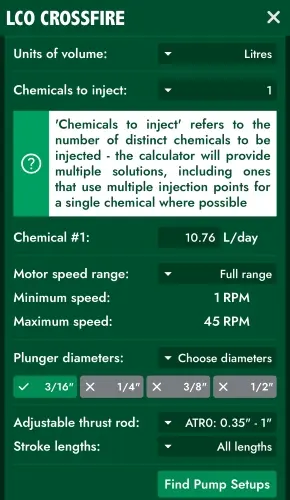

Our ATR (Adjustable Thrust Rod) offers fully customizable stroke lengths—no preset, non-configurable switches. Plus, with our Chemical Calculator in the iOS & Android app, the system provides exact pump configuration settings for precision and savings.

Simplicity in Remote Operations

The LCO CROSSFIRE units seamlessly integrate into your operations, supporting standard Modbus RS-232, RS485, and Ethernet TCP/IP, alongside intuitive apps available on the App Store.

With full remote monitoring and control, every tag accessible through the app can be adjusted in real time. Need to verify or tweak something? CROSSFIRE calculates the exact injection rate based on current speed, allowing for instant adjustments with confidence.

Why choose CROSSFIRE?

- Flexible Integration: Works effortlessly with existing SCADA systems.

- User-Centric Design: Powerful tools without complexity, empowering operators of all skill levels.

- Efficiency at its Core: Minimize downtime and maximize savings with precise injection control.

Take full control of your chemical injection process—anytime, anywhere.