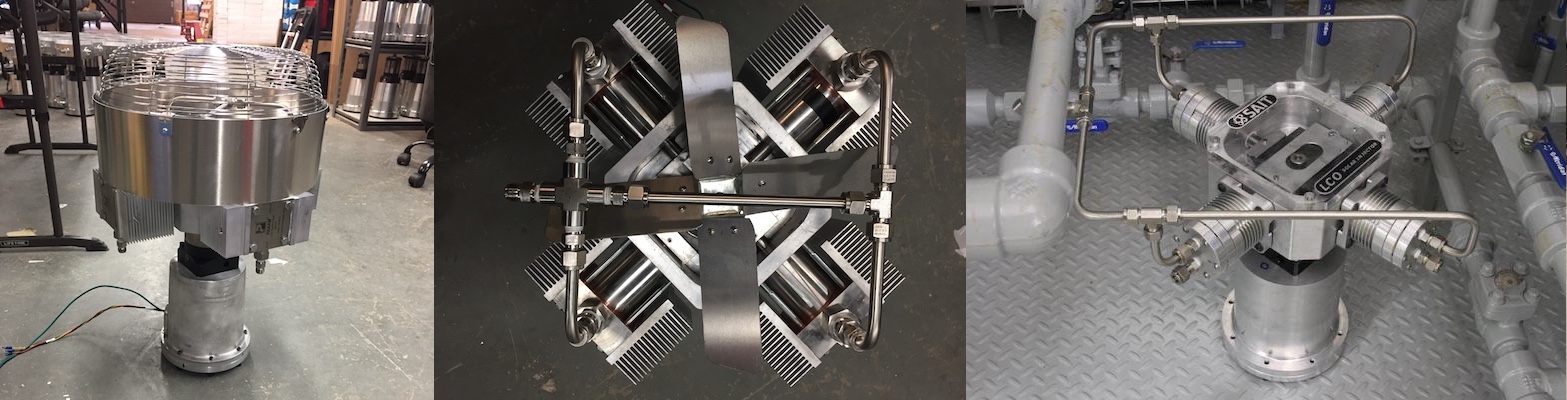

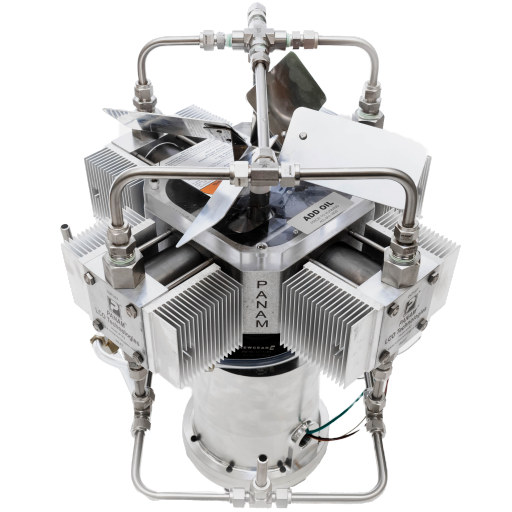

CROSSFIRE Solar Instrument Air Compressor

The LCO Technologies CROSSFIRE Instrument Air Compressor is an ultra-low power device that produces over 1100 Standard Cubic Feet per Day of clean, dry compressed air at 35 PSI using solar power, or over 900 Standard Cubic Feet per Day at 50 PSI. It can allow users to maintain their existing standard pneumatic instrumentation in areas where the goal or requirement is to achieve zero venting.

Features:

- Designed to compress air to drive pneumatic instrumentation, eliminating methane venting

- Produces over 1100 Standard Cubic Feet per Day at 35 PSI

- Continuous duty rated

- Low power consumption with no inrush

- Compressor modulates when used with a pressure transmitter optimizing power consumption

- Simple robust design with easy field serviceability

- Minimal maintenance, a little grease is all that is needed

- Substantially less expensive than vaporized propane, the payback relative to the cost of the propane can be less than 3 months – put that propane budget back on the bottom line

Resources:

Ordering:

For order inquiries within Canada, please contact Spartan Controls:

info@spartancontrols.com

1-877-278-6404

For all international order inquiries, please contact LCO Technologies:

info@lcotechnologies.com

1-403-860-9899